The organic foods products are limited

Electronica Mechatronic Systems (I) Pvt Ltd., known in Indian Machine Tool Market as EMS, was established in 1986 in Pune, India.

The company was established with the aim of developing machine tool accessories indigenously. Its first product was Optical Encoders, with technology transferred from Europe. For the first time, world-class encoders were available to Indian machine tool manufacturers and users at affordable prices. The journey began with inhouse manufacturing of encoders - Glass and magnetic; linear and rotary; incremental and absolute!

Around 2008, we started manufacturing metrology equipment with Height Gauge, soon expanding into video measuring systems and five different types of Coordinate Measuring Machines.

Today, we also design and manufacture special-purpose machines (SPMs) for customized measurement and inspection applications. We are a proud supplier of SPMs to the Indian Défense, Department of Nuclear Energy, Indian Railways, Steel and Mining Industry, and Medical Equipment Manufacturers.

In 2020, we diversified into Railways with indigenously developed automatic gauges for railway wheels and tracks. We continue to grow this portfolio steadily responding to other inspection needs in this vertical.

All existing products are regularly upgraded in features, look and feel to meet market expectations.

EMS looks forward to hearing from you.

We understand that how we are perceived as a company depend s upon what experience we provide to customer. We also understand that this will have to be a continuous process, orchestrated by planning, passion and performance. We are guided by our core values of

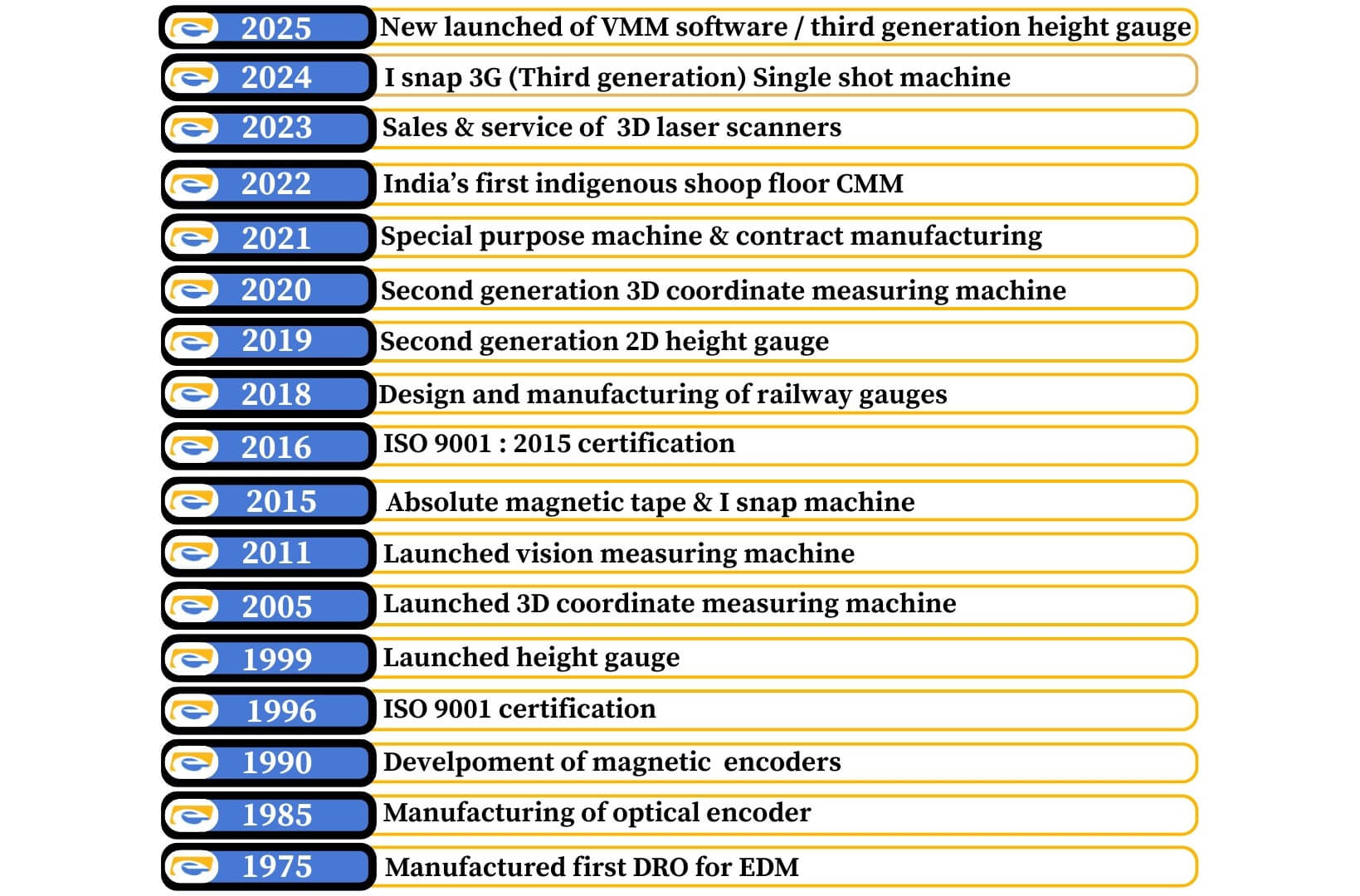

Our Journey

How of what we do

To manufacture reliable products, with consistent performance at a competitive price, we have robust in-house processes. Quality is not the means to achieve something but it is the way to do everything at EMS here. We strive hard to imbibe culture where focused attention and proactiveness are valued attributes so that Quality becomes the way to do things.

Our state of art R&D is equipped with prototype manufacturing. Kaizen, implementation of new manufacturing techniques and automation of processes add scalability. The client relationship which begins with product sale, then becomes a partnership based on mutual trust and respect.

The assembly department is housed in an anti-static and dust free environment. Equipped with a semi-automated production line, the assembly of a variety of products is done by highly skilled workers using an in-house designed software, hardware, test equipment, jigs and fixtures.

Automated Surface Mounting Technology (SMT) line is employed for manufacturing PCB. The SMT facility helps in minimising contamination and eliminates common defects like wrong polarity, dry solder, no solder and wrong component placement. This enhances the product quality, increases productivity and helps attain a cost effective production cycle with minimum lead-time in order execution.

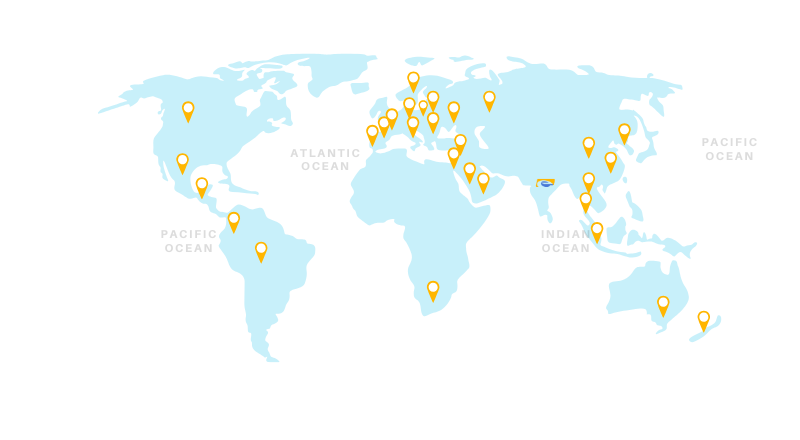

With more than 10000 encoders in the Global market, EMS has well established sales and marketing network. Our Pan India presence, with more than 30 sales engineers and Area Managers, helps reach out to customer faster. Our prompt response and culture of accountability has gained us more than 5000 happy customers.

Exports contribute major part of our turnover. We are represented by a number of dealers all across the globe and the relationship is based on trust and mutual respect.

Our relationship with customer begins with conclusion of sale. We understand what a crucial role after sales service plays to satisfy and to retain customers. At EMS, service is considered a value adding activity that generates loyal customers and increases brand value.

EMS has a team of well trained experienced engineers, well spread all over India. Whenever a customer needs our support, an EMS engineer is always available nearby to make sure that our customer gets full value from our product.

Our engineers undergo rigorous training and are well versed with features and functionality of our products. Their skill and knowledge is routinely updated and tested so that there is minimum inconvenience to the customer.